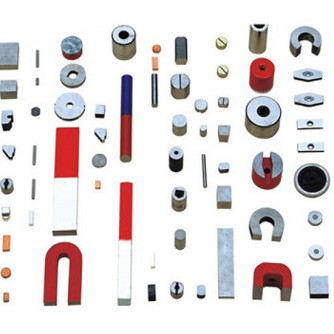

Magnet Shape

In the compression molding process, NdFeB powder is compounded with thermosetting resins. The actual pressing operation is carried out in tools and machines commonly used in powder metallurgy.

After they have been shaped, the moldings are thermally cured to give them mechanical stability.

The materials can be compression molded to form common shapes such as blocks, disks, rings, flat sections and segments with and without holes. The higher filling level and resulting increase in density considerably enhance the magnetic properties in comparison with injection-molded products.

After they have been shaped, the moldings are thermally cured to give them mechanical stability.

The materials can be compression molded to form common shapes such as blocks, disks, rings, flat sections and segments with and without holes. The higher filling level and resulting increase in density considerably enhance the magnetic properties in comparison with injection-molded products.

Process of Bonded compression NdFeB Magnets (for example)