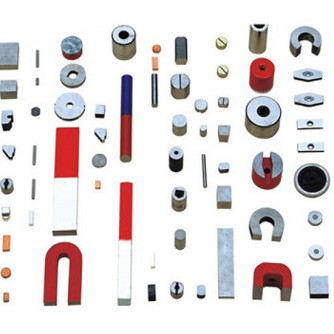

Magnet Shape

Alnico has a low coercive force, and is easily demagnetized if not handled with care. For optimum performance of Alnico 5, the magnetic length should be approximately 5 times the pole diameter or equivalent diameter.

|

|

Application field

The AlNiCo magnet application newly developed hall-effect and MR-based automotive electronic sensors. The traditional applications include magneto, TWT amplifiers, actuators, and instrument.

Magnetic Properties

|

Grade |

Remanence(Br) |

Coercivity Force(Hcb) |

Max. Energy Product(BHmax) |

Maximum Operating Temp. |

US Standard |

IEC Standard |

|||

|

mT |

kGs |

kA/m |

kOe |

kJ/m3 |

MGOe |

||||

|

*LN10 |

650 |

6.5 |

42 |

0.53 |

10 |

1.2 |

450 ℃ |

Alnico 3 |

Alnico 9/3 |

|

*LNG11 |

720 |

7.2 |

37 |

0.48 |

11.2 |

1.4 |

450 ℃ |

Alnico 1 |

Alnico 8/4 |

|

*LNG13 |

700 |

7 |

50 |

0.62 |

13 |

1.6 |

450 ℃ |

Alnico 2 |

Alnico 12/6 |

|

LNG16 |

800 |

8 |

53 |

0.66 |

16 |

2 |

525 ℃ |

[Alnico 4] |

/ |

|

LNG34 |

1180 |

11.8 |

44 |

0.55 |

35 |

4.3 |

525 ℃ |

[Alnico5C] |

/ |

|

LNG37 |

1180 |

11.8 |

48 |

0.60 |

37 |

4.65 |

525 ℃ |

[Alnico5C] |

Alnico 37/5 |

|

LNG40 |

1220 |

12.2 |

48 |

0.60 |

40 |

5 |

525 ℃ |

Alnico 5 |

/ |

|

LNG44 |

1220 |

12.2 |

52 |

0.65 |

44 |

5.5 |

525 ℃ |

Alnico 5 |

Alnico 44/5 |

|

LNG52 |

1250 |

12.5 |

55 |

0.69 |

52 |

6.5 |

525 ℃ |

Alnico5DG |

Alnico 52/6 |

|

LNG60 |

1300 |

13 |

56 |

0.70 |

60 |

7.5 |

525 ℃ |

Alnico 5~7 |

/ |

|

LNGT18 |

580 |

5.8 |

90 |

1.13 |

18 |

2.26 |

550 ℃ |

[Alnico 8] |

Alnico 17/9 |

|

LNGT28 |

1050 |

10.5 |

56 |

0.70 |

28 |

3.5 |

550 ℃ |

Alnico 6 |

Alnico 26/6 |

|

LNGT32 |

800 |

8 |

104 |

1.30 |

34 |

4.25 |

550 ℃ |

Alnico 8 |

Alnico 38/11 |

|

LNGT38 |

820 |

8.2 |

110 |

1.38 |

38 |

4.75 |

550 ℃ |

Alnico 8 |

Alnico 38/11 |

|

LNGT44 |

880 |

8.8 |

120 |

1.50 |

44 |

5.5 |

550 ℃ |

Alnico 8 |

/ |

|

LNGT60 |

900 |

9 |

110 |

1.38 |

60 |

7.5 |

550 ℃ |

Alnico 8 |

Alnico 60/11 |

|

LNGT72 |

1050 |

10.5 |

112 |

1.41 |

72 |

9 |

550 ℃ |

Alnico 9 |

/ |

|

LNGT36J |

700 |

7 |

140 |

1.75 |

36 |

4.5 |

550 ℃ |

Alnico8HC |

Alnico 36/15 |