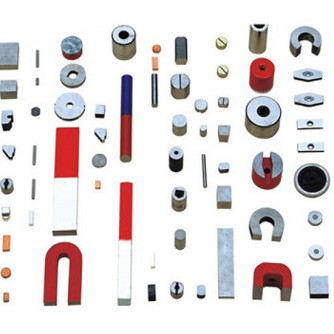

Magnet Shape

Soft ferrite cores are an oxide made from Iron (Fe), Manganese (Mn), and Zinc (Zn) which are commonly referred to as manganese zinc ferrites. They have a low coercivity and are also known as soft magnetic ferrites. Because of their comparatively low losses at high frequencies, they are extensively used in switched-mode power supply (SMPS) and radio frequency (RF) transformers and inductors. Ferrite cores for the high frequency power supply and high quality communication markets are produced in a variety of shapes and sizes for inductors, pulse transformers, high frequency transformers, and noise filters. Notable characteristics of Magnetics ferrite materials are high permeability, good temperature properties, and low disaccommodation. Magnetics offers ten materials. The materials range in permeability from 900µ to 10,000µ and are available in a variety of geometries including toroids, shapes and pot cores. Hardware accessories such as bobbins, printed circuit bobbins, clamps, mounts and headers are also available.

NiZn Ferrite Core

The NiZn ferrite cores has long been well known due to its technological applications in high frequency inductors,

transformer cores, microwave devices, etc. Magnetic properties are determined by chemical composition,

porosity, grain size and micro structure.

Currently, high-frequency MnZn ferrite is used in most cases to develop mini DC-DC converters and inductors.

However, NiZn ferrite cores offers better miniaturization prospects because its high electric resistance exceeding

10 Ohm-m enables NiZn ferrite cores to be wound directly by coils.

Yuxiang Magnetic Materials Ind. Co.,Ltd is a specialist in NiZn cores manufacturing.

Our main product includes:

RI for magnetic shield type core of low profile SMD inductors.

DRWW types and RWW types for choke coils, peaking coils.

R type for fixed inductors.

RID, RHH, R4H types for magnetic shields for r-f coils; low loss magnetic shields, BALUN coil.

SMB type for surface mount.

RH, F, and T type for EMI suppression generated from ribbon cable used in digital equipment, and so on.

MnZn Ferrite Core

MnZn ferrite cores having grain size of about 8~10 μm were produced by controlling the calcination temperature, after-calcination milling time, and sintering conditions. The ferrite powder production conditions and core microstructure were examined to determine their effects on the magnetic properties and mechanical strength of MnZn ferrite cores. A tendency of core loss to decline with a decrease in grain size was confirmed. Strength increased also with a decrease in grain size. Thus, a relation similar to that between strength and fracture toughness in the Equation of Griffith-Irwin was noted. By these findings, it has become possible to produce MnZn ferrite cores with lower loss and greater strength.

The use of MnZn ferrite is spreading from switching power supplies to inductive charging systems for electric vehicles and automated guided vehicles. These inductive charging systems incorporate a connector whose contact transformer has its primary and secondary sides divided in the middle[1]-[3]. The circuit composition of the inductive charging systems adopts a high-frequency switching method of 100 to 370 kHz[4]. Inductive charging systems require lower loss cores for minimizing heat generation during battery charging[1]. They also require cores with a high saturation magnetic flux density to match large current inputs. Moreover, they require cores with greater mechanical strength since electric vehicles are often driven on rough unpaved roads. For these reasons, MnZn ferrite ("6H20" of FDK make) production conditions and core microstructure were examined to determine their effects on the magnetic properties and strength values of MnZn ferrite cores.

NiZn Ferrite Core

The NiZn ferrite cores has long been well known due to its technological applications in high frequency inductors,

transformer cores, microwave devices, etc. Magnetic properties are determined by chemical composition,

porosity, grain size and micro structure.

Currently, high-frequency MnZn ferrite is used in most cases to develop mini DC-DC converters and inductors.

However, NiZn ferrite cores offers better miniaturization prospects because its high electric resistance exceeding

10 Ohm-m enables NiZn ferrite cores to be wound directly by coils.

Yuxiang Magnetic Materials Ind. Co.,Ltd is a specialist in NiZn cores manufacturing.

Our main product includes:

RI for magnetic shield type core of low profile SMD inductors.

DRWW types and RWW types for choke coils, peaking coils.

R type for fixed inductors.

RID, RHH, R4H types for magnetic shields for r-f coils; low loss magnetic shields, BALUN coil.

SMB type for surface mount.

RH, F, and T type for EMI suppression generated from ribbon cable used in digital equipment, and so on.

MnZn Ferrite Core

MnZn ferrite cores having grain size of about 8~10 μm were produced by controlling the calcination temperature, after-calcination milling time, and sintering conditions. The ferrite powder production conditions and core microstructure were examined to determine their effects on the magnetic properties and mechanical strength of MnZn ferrite cores. A tendency of core loss to decline with a decrease in grain size was confirmed. Strength increased also with a decrease in grain size. Thus, a relation similar to that between strength and fracture toughness in the Equation of Griffith-Irwin was noted. By these findings, it has become possible to produce MnZn ferrite cores with lower loss and greater strength.

The use of MnZn ferrite is spreading from switching power supplies to inductive charging systems for electric vehicles and automated guided vehicles. These inductive charging systems incorporate a connector whose contact transformer has its primary and secondary sides divided in the middle[1]-[3]. The circuit composition of the inductive charging systems adopts a high-frequency switching method of 100 to 370 kHz[4]. Inductive charging systems require lower loss cores for minimizing heat generation during battery charging[1]. They also require cores with a high saturation magnetic flux density to match large current inputs. Moreover, they require cores with greater mechanical strength since electric vehicles are often driven on rough unpaved roads. For these reasons, MnZn ferrite ("6H20" of FDK make) production conditions and core microstructure were examined to determine their effects on the magnetic properties and strength values of MnZn ferrite cores.