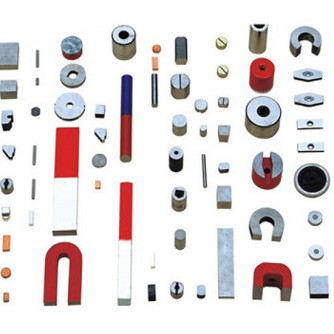

Magnet Shape

INTRODUCTION

Our metallic powder core including five kinds of metallic material:

Iron cores (Fe)

Sendust cores(ALSiFe)

High flux cores (NiFe50)

M.P.P cores (Ni81Mo2

FeSi powder core (FeSi)

which can be used in various application Iron powder as a core material has been widely used. The distributed air gap properties in iron powder cores also make them extremely well suited for a variety of energy storage inductor applications. Iron powder cores is a Cost-Effective design. It can also be used in place of ferrite and ironalloy lamination requiring a gap.

TEMPERATURE EFFECTS

Metallic powder cores are fitted for temperature range from 65℃ to +125℃ . Highest working temperature of type H and Y(with special coat)is 300℃ . Highest working frequency is 600kHz. Testing condition: U=0.3V, =0.3mm Or 0.5 wire, N=10 wires, f=300kHz. When cores are placed in higher temperature, it will make inductance and quality factor (Q) to perpetually decrease. Change in this character is depended on time, temperature core, size and frequency and flux density etc.

FINISH

Toroidal iron powder cores and Bus bar cores are well finished with protecting

paint. The minimum dielectric strength of coating is 600Vrms under 50Hz.The dielectric strength also may be increased according to the needs of customer. The surface of E-shaped and U-shaped cores are treated with antirust material. We suggest the user to carefully store the untreated products to avoid moist and rain.

APPLICATION

Our products mainly used in DC output choke, different mode input choke, power factor correcting inductor, continuous mode flyback inductor , light-adjusting choke and other EMI/RFI circuit. We successfully perfected a lot of high quality iron powder core series products in recent years, which had passed the certification of national grade new product. Main technical properties are up to similar products in China and foreign countries.

Our metallic powder core including five kinds of metallic material:

Iron cores (Fe)

Sendust cores(ALSiFe)

High flux cores (NiFe50)

M.P.P cores (Ni81Mo2

FeSi powder core (FeSi)

which can be used in various application Iron powder as a core material has been widely used. The distributed air gap properties in iron powder cores also make them extremely well suited for a variety of energy storage inductor applications. Iron powder cores is a Cost-Effective design. It can also be used in place of ferrite and ironalloy lamination requiring a gap.

TEMPERATURE EFFECTS

Metallic powder cores are fitted for temperature range from 65℃ to +125℃ . Highest working temperature of type H and Y(with special coat)is 300℃ . Highest working frequency is 600kHz. Testing condition: U=0.3V, =0.3mm Or 0.5 wire, N=10 wires, f=300kHz. When cores are placed in higher temperature, it will make inductance and quality factor (Q) to perpetually decrease. Change in this character is depended on time, temperature core, size and frequency and flux density etc.

FINISH

Toroidal iron powder cores and Bus bar cores are well finished with protecting

paint. The minimum dielectric strength of coating is 600Vrms under 50Hz.The dielectric strength also may be increased according to the needs of customer. The surface of E-shaped and U-shaped cores are treated with antirust material. We suggest the user to carefully store the untreated products to avoid moist and rain.

APPLICATION

Our products mainly used in DC output choke, different mode input choke, power factor correcting inductor, continuous mode flyback inductor , light-adjusting choke and other EMI/RFI circuit. We successfully perfected a lot of high quality iron powder core series products in recent years, which had passed the certification of national grade new product. Main technical properties are up to similar products in China and foreign countries.