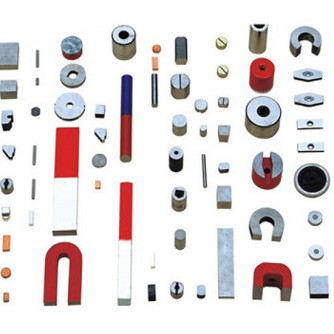

Magnet Shape

The advantage of the injection molding process for producing magnets lies in the wide range of shapes that can be produced. It is also possible for inserts such as axles, bushes or rings to be molded in, with the inserts being loaded by hand or fully automatically, depending on the quantity produced. The costs of assembly operations can be reduced as such materials allow press-fit, snap-fit and positive-fit connections with motor shafts etc.

The production process allows products to be manufactured within such tight tolerances that no reworking is generally necessary. As required, polymer-bonded materials can be turned, drilled, milled and ground and they are not as brittle as sintered materials.

The proportion of plastic materials(PA06, PA12 and PPS) of typically ten percent by weight mean that the magnetic properties lie below those of unmixed material. On the other hand, with anisotropic grades, it is possible to achieve a directional magnetization during the injection molding process. This in turn improves the magnetic properties.

Process of Injection Bonded Magnets ( NdFeB for example)

The production process allows products to be manufactured within such tight tolerances that no reworking is generally necessary. As required, polymer-bonded materials can be turned, drilled, milled and ground and they are not as brittle as sintered materials.

The proportion of plastic materials(PA06, PA12 and PPS) of typically ten percent by weight mean that the magnetic properties lie below those of unmixed material. On the other hand, with anisotropic grades, it is possible to achieve a directional magnetization during the injection molding process. This in turn improves the magnetic properties.

Process of Injection Bonded Magnets ( NdFeB for example)