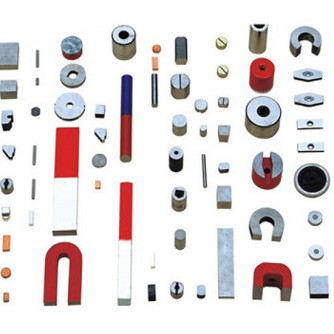

Magnet Shape

1. Our bonded SmCo magnet is made with ground sintered SmCo magnet.

2. The powder is mixed with resin and molded like NdFeB bonded magnet.

3. Various shapes of high dimensional accuracy can be produced without further processing.

4. Due to excellent corrosion resistance, coating is not required.

5. Compression bonded magnets are available using many isotropic neodymium iron boron material grades as well as crushed & powdered samarium cobalt materials.

6. Combinations of different material grades may also be used to create specific magnetic characteristics.

7. Compression bonded SmCo magnets offers higher magnetic strength than injection molded SmCo magnets due to their higher magnetic particle density, but are limited to simpler geometries. The epoxy binder used is resistant to normal industrial solvent and automotive fluids.

|

|

Application field

The Compression Bonded SmCo magnet not only has high accuracy, various shape, characteristics, but also the strong corrosion resistance, generally without surface treatment, as well as the high temperature stability. Bonded SmCo magnet mainly applications are servo-motors, pump couplings, and sensors.

Magnetic Properties

|

Grade |

Remanence(Br) |

Coercivity Force(Hcb) |

Intrinsic Coercive Force(Hcj) |

Max. Energy Product(BHmax) |

maximum Operating Temp. |

||||

|

mT |

kGs |

kA/m |

kOe |

kA/m |

kOe |

kJ/m3 |

MGOe |

||

|

PBS-4T |

380~420 |

3.8~4.2 |

200~280 |

2.5~3.5 |

640~1030 |

8.0~13.0 |

28~36 |

3.5~4.5 |

150℃ |

|

PBS-5T |

410~540 |

4.1~5.4 |

265~360 |

3.3~4.5 |

640~1200 |

8.0~15.0 |

36~44 |

4.5~5.5 |

150℃ |

|

PBS-9 |

610~660 |

6.1~6.6 |

415~480 |

5.2~6.0 |

640~1200 |

8.0~15.0 |

68~76 |

8.5~9.5 |

150℃ |

|

PBS-11 |

640~720 |

6.4~7.2 |

430~510 |

5.4~6.4 |

640~1200 |

8.0~15.0 |

76~88 |

9.5~11.0 |

150℃ |